Frontier helps Arbor build a “vegetarian rocket engine” to power data centers

Frontierthe organization supported by Stripe, Google and Meta announced that it will pay the startup on Tuesday Arbor Energy By the end of the decade, it will remove 116,000 tons of carbon dioxide.

With the agreement, Arbor will help build the first commercial-scale power plant in southern Louisiana, discarding biomass and generating electricity for the data center. At the same time, isolate the resulting co2shipped via pipeline and buried underground.

“We can sell it as two products,” Arbor co-founder and CEO Brad Hartwig told TechCrunch. “We sell carbon-free base loading energy and pure (carbon) removal.”

Twofer is inherent to a technology called BICR or a technology called biomass carbon removal and storage.

“One of the great things about BICRS is that you get the captured portion for free as the plants are pulling CO down.2and all you have to do is remove it and store it,” Hannah Bevington, head of deployment at Frontier, told TechCrunch.

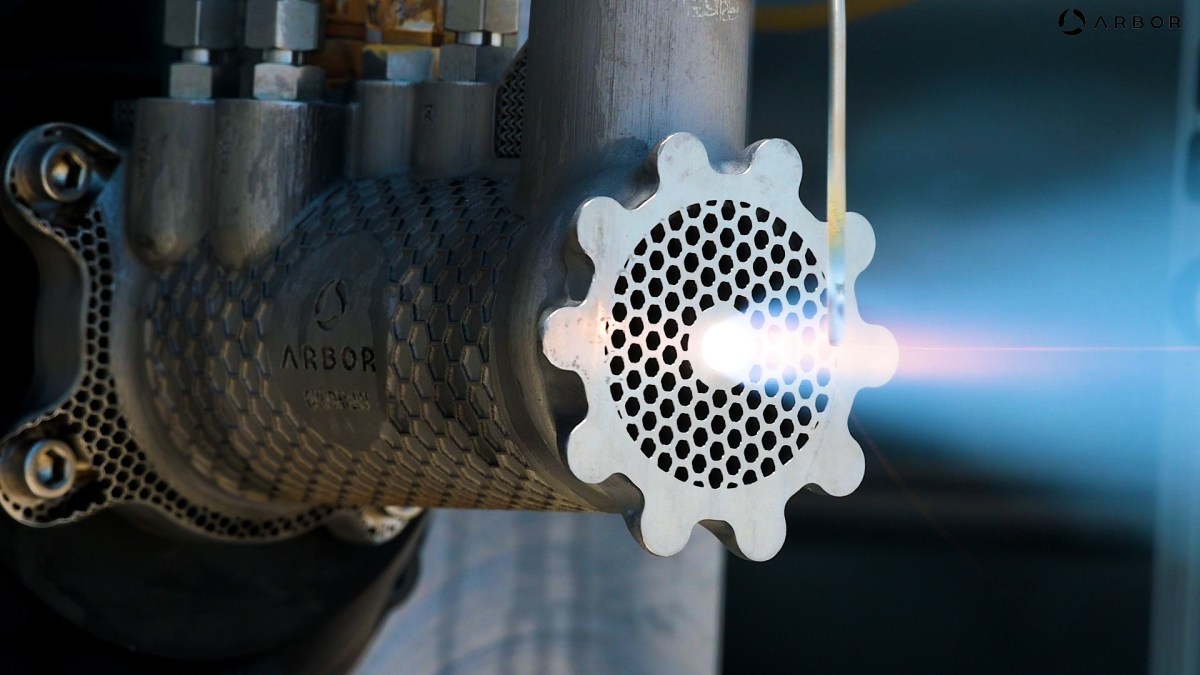

Although the burning of biomass is older than human civilization, Arbor gives this practice a space-age twist. Heartwig, who? I used to work at SpaceXinspired by Rocket Turbo Kinary in the development of the Arbor power plant. The company’s first facility generates between 5 and 10 megawatts of electricity. Hartwig said the company is working to steadily improve production volumes.

At power plants, waste biomass is first converted to syngas. The startup had previously intended to use ready-made gas agents, but they never sniffed any of them, so they developed their own. In gas agents, Supercritical Co.2 – Carbon dioxide under vast pressure – What is fed from the power plant itself helps to dissolve the biomass and releases hydrogen and carbon monoxide gas.

Syngas and Co2 Then head to the fuel chamber, where the syngas is burned using pure oxygen. This produces water vapor, heat, and more carbon dioxide. (The existence of co2 The combustion chamber is designed, Hartwig said, which helps to alleviate the temperature so that the metal in the machine does not melt.

The hot gas is then fed through the turbomatinee to generate electricity. Most cooperatives2 It is decoupled into the pipeline and transported for permanent storage, but some of it will be reverted to gasoline.

Hartwig previously appropriately explained A power plant as a “vegetarian rocket engine.”

The entire system captures 99% of CO2 Due to combustion, it is much higher than competing methods. Also, this process removes carbon from the atmosphere as it burns biomass.

Bebbington said Frontier estimates that between 1 and 5 gigatons of waste biomass is available each year. However, not all biomass is created equally. Some may need to transport longer distances. Others may break it down on the farm to fertilize it.

When reviewing carbon removal, “I want to note that we take that into consideration.” She said. “It also requires that every ton provided meet sustainable biomass principles in a very clear way.”

Even if only one gigaton meets these criteria, BICRS and its close cousin, Carbon Capture and Sequestration (BECCS), have many potential to create major dents in future energy needs.

In the case of frontiers, the arbor burns only the biomass and ensures the power plant removes carbon as requested by trade. Frontier previously supported Arbor with pre-purchase agreements.

Arbor power plants can theoretically burn hydrocarbon sources, including natural gas. “The system is specially designed to be fuel-flexible,” Hartwig said.

“BECCS wants to be a major player in data centers, industrial electrification and grid resilience,” Hartwig said. “But if you have new fossil assets built, we hope they all have zero emissions. Let’s capture all of these emissions.”